Milling machine manuals are essential guides for safe operation, installation, and maintenance. They provide detailed instructions for optimal performance and troubleshooting, ensuring efficiency and accuracy in machining tasks.

1.1 Importance of Milling Machine Manuals

Milling machine manuals are crucial for safe and efficient operation, providing detailed guidance on installation, maintenance, and troubleshooting. They ensure proper usage, compliance with safety standards, and optimal performance, reducing errors and enhancing productivity. These manuals serve as indispensable resources for operators, technicians, and manufacturers, covering essential procedures and best practices for milling machinery.

1.2 Key Components Covered in the Manuals

Milling machine manuals typically include detailed sections on machine components, operational procedures, safety protocols, maintenance schedules, and troubleshooting guides. They cover essential parts like the spindle, table, and feed mechanisms, ensuring comprehensive understanding for operators. Additionally, these manuals provide instructions for CNC programming, lubrication, and error resolution, making them a vital resource for effective machine utilization and longevity.

Safety Precautions

Always ensure the work area is clean and free of hazards. Proper training and adherence to safety protocols are crucial to prevent accidents during milling operations.

2.1 Pre-Operational Safety Checks

Before starting the milling machine, perform thorough inspections. Ensure all guards are in place, tools are secure, and the work area is clear of debris. Check spindle speed settings, emergency stops, and lubrication levels. Verify that all controls function properly and no loose clothing or jewelry could obstruct operations. Always start the machine in manual mode to test for any malfunctions or unusual noises. This step ensures a safe working environment and prevents potential accidents. Regular maintenance and adherence to these checks are vital for optimal performance and operator safety.

2.2 Emergency Procedures

In case of an emergency, press the emergency stop button immediately to halt the machine. Ensure the power supply is isolated before attempting any repairs. Evacuate the area if there’s a risk of fire or chemical exposure. Never restart the machine without conducting a thorough safety check. Keep emergency contact numbers accessible and ensure all operators are trained in these procedures to minimize risks and ensure safe operations.

Installation and Setup

Proper installation ensures optimal performance. Place the machine on a sturdy, level surface, connect power, and follow manual instructions for alignment and initial setup procedures carefully.

3.1 Initial Installation Steps

Begin by carefully uncrating and inspecting the machine for damage. Place it on a sturdy, level surface and ensure proper grounding. Connect the power supply as specified in the manual, ensuring all electrical connections are secure.Mount any optional accessories according to the manufacturer’s instructions. Double-check that all components are properly aligned and tightened before proceeding to leveling and alignment steps.

3.2 Leveling and Aligning the Machine

Using precision tools, level the machine on its base to ensure accurate operation. Adjust the leveling feet carefully to achieve a stable, even surface. Align the spindle axis with the worktable, following the manual’s specifications. Double-check all adjustments to ensure proper alignment, which is critical for precise milling operations and tool longevity. Use shims if necessary for fine-tuning the alignment.

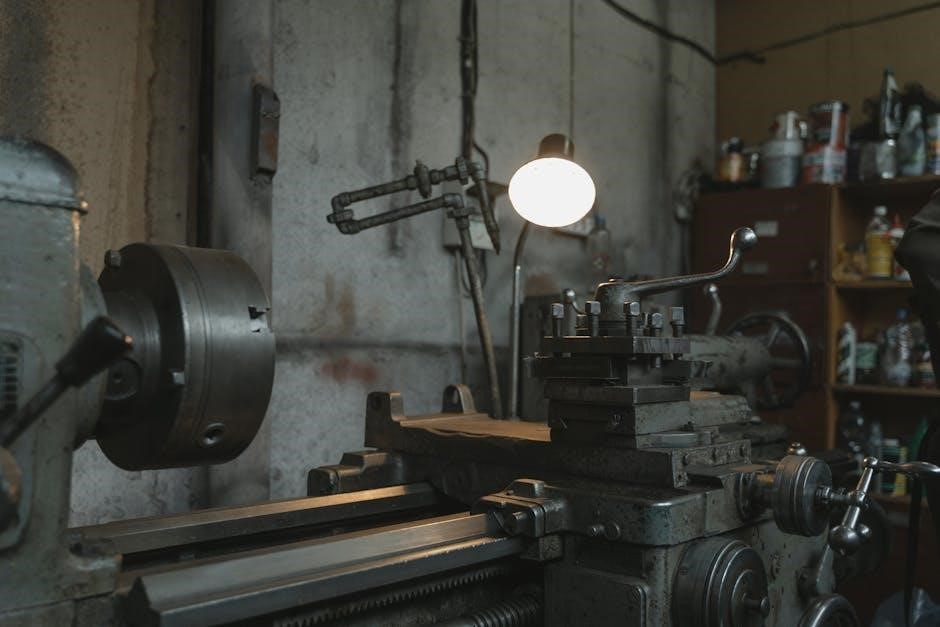

Basic Machine Parts

Milling machines consist of key components like the spindle, worktable, and coolant system. Understanding these parts is crucial for effective operation and maintenance.

4.1 Overview of Milling Machine Components

Milling machines are composed of essential structural and functional components. Key elements include the base, column, knee, spindle, worktable, saddle, and swivel table. These parts ensure stability, precision, and versatility in machining operations, enabling accurate material processing and tool movement.

4.2 Functions of Each Part

The base provides structural stability, while the column houses the spindle and supports the machine. The knee adjusts vertically to position workpieces accurately. The spindle holds cutting tools, rotating them at precise speeds. The worktable facilitates material movement, and the saddle and swivel table enable horizontal and angular adjustments, ensuring versatile and precise machining operations for various applications.

Operating the Milling Machine

Start the machine in manual mode, ensure proper adjustments, and monitor operations closely. Trained operators should follow safety guidelines to achieve precise and efficient milling results consistently.

5.1 Starting and Stopping the Machine

Ensure all safety protocols are followed before starting. Power up the machine in manual mode, check for unusual noises, and verify spindle movement. To stop, reduce speed gradually and engage the emergency stop if necessary. Always monitor the machine during operation to prevent accidents and ensure smooth functionality. Proper shutdown procedures are crucial for machine longevity and operator safety.

5.2 Feeding and Speed Control

Proper feeding rates and speed control are critical for precise milling operations. Adjust the feed rate based on material type and tooling, ensuring minimal vibration. Use the machine’s speed control to optimize spindle RPM for different materials and tools. Maintain consistent feed to avoid tool wear and achieve desired surface finishes. Always refer to manual guidelines for specific material recommendations and operational best practices to ensure efficiency and safety.

Maintenance and Lubrication

Regular maintenance and lubrication are crucial for extending the milling machine’s lifespan. Clean and inspect parts daily, lubricate moving components, and follow the schedule to prevent wear and ensure smooth operation.

6.1 Regular Maintenance Tasks

Regular maintenance tasks for milling machines include cleaning the machine, inspecting parts for wear, and ensuring proper alignment. Lubricate moving components as per the schedule, check spindle brakes, and verify drive belt tension. Periodic inspection of coolant systems and chip removal mechanisms is also essential to maintain optimal performance and prevent unexpected downtime.

6.2 Lubrication Schedule

A well-defined lubrication schedule is crucial for milling machines. Apply oil to spindle bearings and gears daily, while grease should be added to slides and ways weekly. Ensure coolant systems are filled and maintained regularly. Follow the manufacturer’s recommendations for lubricant types and intervals to reduce friction and wear, ensuring smooth operation and extending machine longevity.

Troubleshooting Common Issues

Common issues include error codes, vibrations, and spindle misalignment. Refer to diagnostic guides for resetting errors and adjusting components to restore optimal machine performance quickly.

7.1 Identifying Faults

Identifying faults in milling machines involves checking error codes, unusual noises, and performance issues. Manuals provide diagnostic charts to pinpoint problems like misaligned spindles or faulty sensors; Regular maintenance and log reviews help operators detect issues early, ensuring timely repairs and minimizing downtime. Always refer to the troubleshooting section for precise fault identification and resolution steps.

7.2 Resetting Errors

Resetting errors on milling machines often involves powering off, checking connections, and restarting. Manuals detail specific reset procedures for error codes, such as clearing alarms or recalibrating systems. Ensure all safety protocols are followed before resetting to prevent further issues and maintain operational integrity. Always consult the manual for model-specific reset instructions to avoid complications.

Advanced Features and Functions

Advanced milling machines offer CNC operations, custom programming, and model-specific enhancements like Bridgeport and Sinumerik systems, enabling precision machining and complex design execution with ease.

8.1 CNC Milling Operations

CNC milling operations integrate advanced automation, enabling precise and efficient machining. These systems support custom programming, real-time monitoring, and automated workflows, ensuring high accuracy. They are compatible with models like the Bridgeport Series 1 and Sinumerik 808D, offering features such as tool path optimization and material handling, enhancing productivity and reducing errors in complex machining tasks.

8.2 Custom Programming

Custom programming in CNC milling allows users to define specific machining sequences, optimizing tool paths and material handling. It supports the creation of custom cycles and integrates with CAD/CAM software for precise operations. Advanced systems offer real-time monitoring and error corrections, enhancing efficiency and adaptability in complex projects, ensuring high-quality outcomes tailored to individual requirements.

Parts and Accessories

Milling machines include standard and optional parts like cutters, collets, and coolant systems. Accessories enhance functionality, while digital resources provide detailed specifications and compatibility for various models.

9.1 Standard and Optional Parts

Milling machine manuals detail standard parts like cutters, collets, and spindle locks, essential for basic operations. Optional accessories, such as coolant systems and digital readouts, enhance functionality. These parts are available from manufacturers or online forums, ensuring compatibility and performance. They are crucial for maintaining and upgrading the machine effectively, optimizing its capabilities.

9.2 Where to Source Parts

Parts for milling machines can be sourced from manufacturer websites, authorized distributors, or online forums. Many manuals provide direct links or part numbers, ensuring authenticity. Retailers like Amazon and eBay also offer a wide range of accessories. Additionally, community forums and specialized machine shops are reliable sources for rare or discontinued components, ensuring easy access to necessary parts.

Training and Certification

Training and certification programs ensure operators master milling machine operation, safety, and troubleshooting. Manufacturers and technical institutions offer courses, enhancing expertise and workplace safety.

10.1 Operator Training

Operator training is crucial for mastering milling machine operations. Programs cover safety protocols, machine setup, and troubleshooting. Hands-on practice ensures proficiency in handling tools and materials, adhering to manufacturer guidelines for optimal performance and workplace safety.

10.2 Certification Programs

Certification programs validate operators’ skills in milling machine operations. These programs often include theoretical and practical assessments, ensuring compliance with industry standards. Certifications enhance credibility and career opportunities, demonstrating expertise in safe and efficient machine operation, maintenance, and troubleshooting.

Manufacturer-Specific Manuals

Manufacturer-specific manuals provide detailed instructions tailored to individual milling machine models. They cover unique features, maintenance, and troubleshooting specific to the maker, ensuring optimal performance.

11.1 Bridgeport Series Manuals

Bridgeport series manuals are comprehensive guides for installation, operation, and maintenance of Bridgeport milling machines. They include detailed parts lists, troubleshooting tips, and specific instructions for models like the Series I, ensuring operators can maximize efficiency and maintain machine accuracy. These manuals are essential for both novice and experienced users.

11.2 Other Popular Models

Other popular milling machine models include the Concept MILL 55 and SANY SCM500-3, each with unique features and operational guidelines. Their manuals cover installation, maintenance, and troubleshooting, ensuring optimal performance. These resources are crucial for operators to understand specific functionalities and maintain machine longevity, tailored to their respective models’ advanced capabilities and design specifications.

Digital Resources and Downloads

Digital resources for milling machine manuals include downloadable PDFs, interactive guides, and online forums. These materials provide comprehensive instructions, troubleshooting tips, and maintenance schedules, accessible for free or purchase.

12.1 Availability of PDF Manuals

PDF manuals for milling machines are widely available online, offering detailed guides for operation, maintenance, and troubleshooting. Many manufacturers provide free downloads, while forums and websites host comprehensive libraries. Popular models like the Bridgeport Series and Concept MILL 55 have dedicated PDF resources, ensuring easy access to essential information for optimal machine performance and user safety.

12.2 Online Communities and Forums

Online forums and communities are vital resources for milling machine users, offering discussions on manuals, troubleshooting, and best practices. Platforms host interactive guides, user-generated content, and expert advice, fostering collaboration and knowledge sharing among operators and technicians, ensuring they stay updated on the latest techniques and solutions for milling machine operation and maintenance.